-

Vehicle Parts

-

-

Heading title

-

Exhausts

Exhausts

-

Intake & Cooling

Intake & Cooling

-

Suspension & Chassis

Suspension & Chassis

-

Brakes

Brakes

-

Engine

Engine

-

Electrics

Electrics

-

Fuel & Ignition

Fuel & Ignition

-

Wheels & Tyres

Wheels & Tyres

-

Clutch & Transmission

Clutch & Transmission

-

Styling & Body Kits

Styling & Body Kits

-

Accessories

Accessories

-

Fluids & Lubrication

Fluids & Lubrication

-

Turbos & Induction

Turbos & Induction

-

Cleaning & Detailing

Cleaning & Detailing

- Pre Wash

- Shampoo

- Decomtamination

- Wheels

- Clay bar & Lube

- Hand Polish

- Cermic Coating

- Carnauba Wax

- Sealants

- Glass Cleaner

- Quick Detail

- Metal Polish

- Tyre Dressing

- Leather

- Fabric

- Multi Surface

- Scents & Freshners

- Applicators

- Buckets

- Detailing Brushes

- Microfibres & Towels

- Foam Lances & Pump Sprayers

- Wash Mitts & Pads

- Storage

-

Service & Maintenance

Service & Maintenance

-

-

-

- Brands

- Software & Tuning

- Service Kits

- New Arrivals

- Deals

-

Services

-

-

Services

- VW- Audi Group - Dealer Level Diagnostics - ODIS

- Performance Parts Fitting

- Servicing & Repair

- Full Geometry Hunter Four Wheel Alignment

- Gearbox DSG Repair Service

- Haldex Servicing

- DRC Suspension Specialist

- Walnut Blasting De-coke Service

- ADAS ACC Set Up

- Wheels and Tyres

- MOT Testing

- Timing Belts and Chains

-

-

-

Vehicle Parts

-

-

Heading title

-

Exhausts

Exhausts

-

Intake & Cooling

Intake & Cooling

-

Suspension & Chassis

Suspension & Chassis

-

Brakes

Brakes

-

Engine

Engine

-

Electrics

Electrics

-

Fuel & Ignition

Fuel & Ignition

-

Wheels & Tyres

Wheels & Tyres

-

Clutch & Transmission

Clutch & Transmission

-

Styling & Body Kits

Styling & Body Kits

-

Accessories

Accessories

-

Fluids & Lubrication

Fluids & Lubrication

-

Turbos & Induction

Turbos & Induction

-

Cleaning & Detailing

Cleaning & Detailing

- Pre Wash

- Shampoo

- Decomtamination

- Wheels

- Clay bar & Lube

- Hand Polish

- Cermic Coating

- Carnauba Wax

- Sealants

- Glass Cleaner

- Quick Detail

- Metal Polish

- Tyre Dressing

- Leather

- Fabric

- Multi Surface

- Scents & Freshners

- Applicators

- Buckets

- Detailing Brushes

- Microfibres & Towels

- Foam Lances & Pump Sprayers

- Wash Mitts & Pads

- Storage

-

Service & Maintenance

Service & Maintenance

-

-

-

- Brands

- Software & Tuning

- Service Kits

- New Arrivals

- Deals

-

Services

-

-

Services

- VW- Audi Group - Dealer Level Diagnostics - ODIS

- Performance Parts Fitting

- Servicing & Repair

- Full Geometry Hunter Four Wheel Alignment

- Gearbox DSG Repair Service

- Haldex Servicing

- DRC Suspension Specialist

- Walnut Blasting De-coke Service

- ADAS ACC Set Up

- Wheels and Tyres

- MOT Testing

- Timing Belts and Chains

-

-

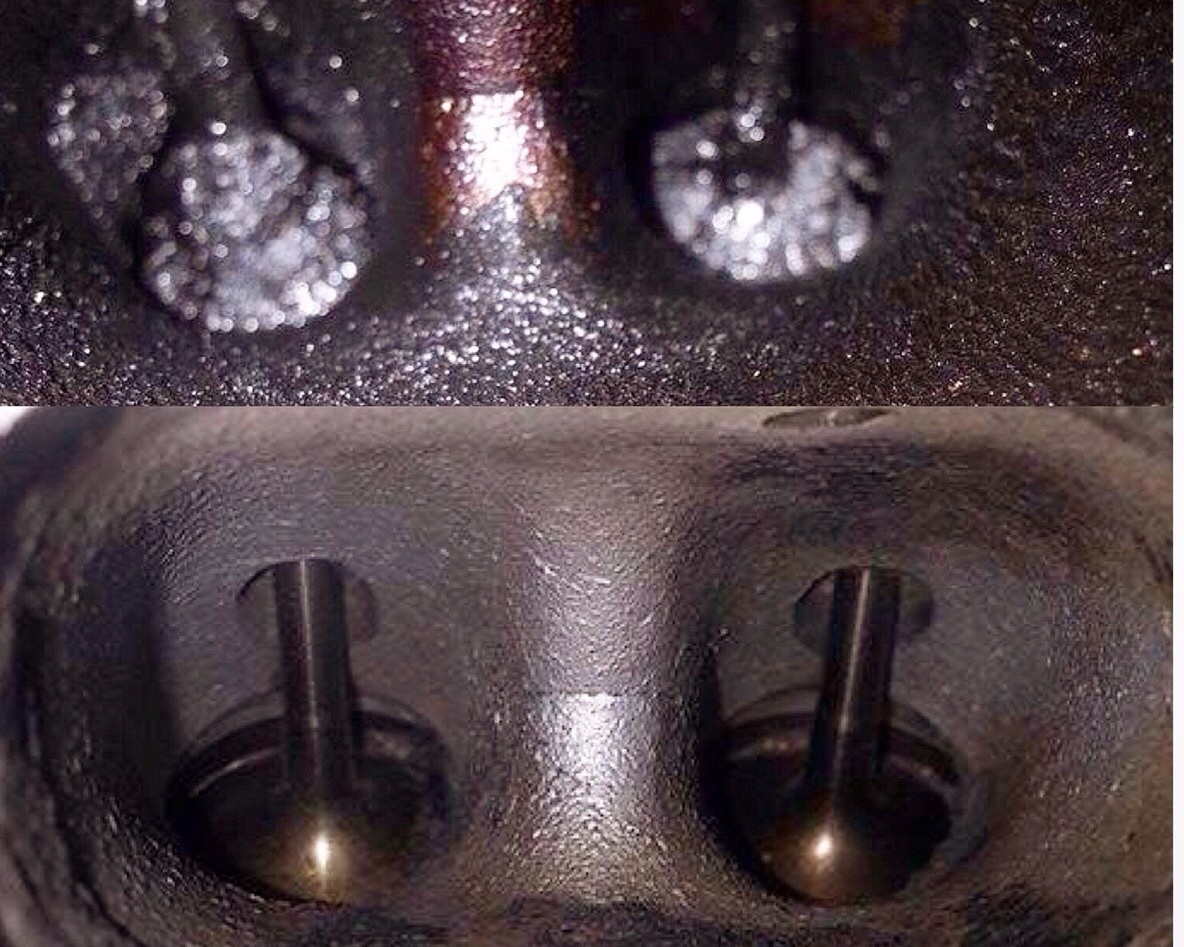

Walnut Blasting De-coke Service

Need help? We're available at 0113 250 8333 or Email us at service@moorfieldgermanmotors.co.uk